Hot rolled steel products are used in pipe production, general structure and cold forming applications.

Production Range, Steel Roll

| Thickness: | 1.5 – 10 mm |

| Width: | 550 – 1000 mm |

Production Range, Patterned Sheet

| Thickness: | 2-2.5-3-4-5 mm |

| Width: | 1000 mm |

Production Standards & Steel Qualities

DIN EN 10111-10255-10025-2-10149-2-SAE J403- API 5L-API 5 CT

Patterned Sheet: S235JR

Technical Specifications

| Coil Specifications | Min | Mx |

| Weight (kg/mm x width) | 12.5 | 15.5 |

| Width range (mm) | 550 | 1000 |

| Thickness range (mm) | 1.15 | 10 |

| Inner diameter (mm) | 752 |

772 |

| Outer diameter (mm) | 1600 | 1800 |

| Telescopicity (mm) | 50 | |

| Packing: | One circumferential, three eye banding | |

| Production method: | Steel making by EAF and LF, Slab Casting and Hot Rolling | |

| Width tolerance: | For all width ranges -0; +20 mm | |

-TOS 3350, 3380 contain maximum 0,035 % sulphur

-The values are Chemical Compositions of the ladle analysis

-All tolerances are valid for hot rolled coil (mill edge)

-For TOS-2711, % Cr, %Ni ve % Nb max values are 0.10, 0.10 ve 0.035 respectively

-Thickness tolerance is valid for the measurements 40 mm inside from both edges.

* A50 (%) = 1944 So0,2/U0,9 (So : Cross section, mm2, U : Tensile strength N/mm2)

-Above 4,00 mm thickness, the tensile strength values are : S275JR = 410-600, S355JR = 470-700 N/mm2

-Tolerances are not applicable for both ends (90/thickness, but maximum 20 m)

-For API Grades, an agreement between the producer and the client on the coil mechanical properties to be guaranteed must be reached during ordering.

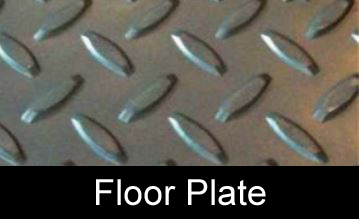

Floor Plates Technical Specification

| 1. | Available Core Thickness (mm): 2.0, 2.5, 3.0, 4.0, 5.0 and Width (mm): 1000 |

| 2. | Core Thickness Tolerance

2.0 mm +/-0.25 mm |

| 3. |

The steel grade used is 235 JR |

| 4. |

Pattern is ASTM teardrop pattern. a, b, c, d, e values are typical. |

| 5. |

Delivery date is given for the order more than 100 tons, smaller tonnage is available from stocked production. |

| 6. |

Weight ranges (kg/m2): |

Quality, Production and Matrices , Click Below